Pietro Odaglia on the Anti-Ruin project and the path it set for his next venture.

Executed in just four weeks, the Anti-Ruin installation was shaped through close collaboration, uniting artistic intent, construction logic, and cutting-edge additive manufacturing.

Anti-Ruin is an installation designed by Levant Ozruh of London-based externe Seite OZRUH, created for the externe Seite 2025 Venice Biennale and presented in two formats: as a monumental sculpture within the Türkiye Pavilion, and as a featured documentary film in the main exhibition space Intelligens CANON. The project offers a compelling response to the Biennale’s overarching theme: Intelligens – Natural. Artificial. Collective.

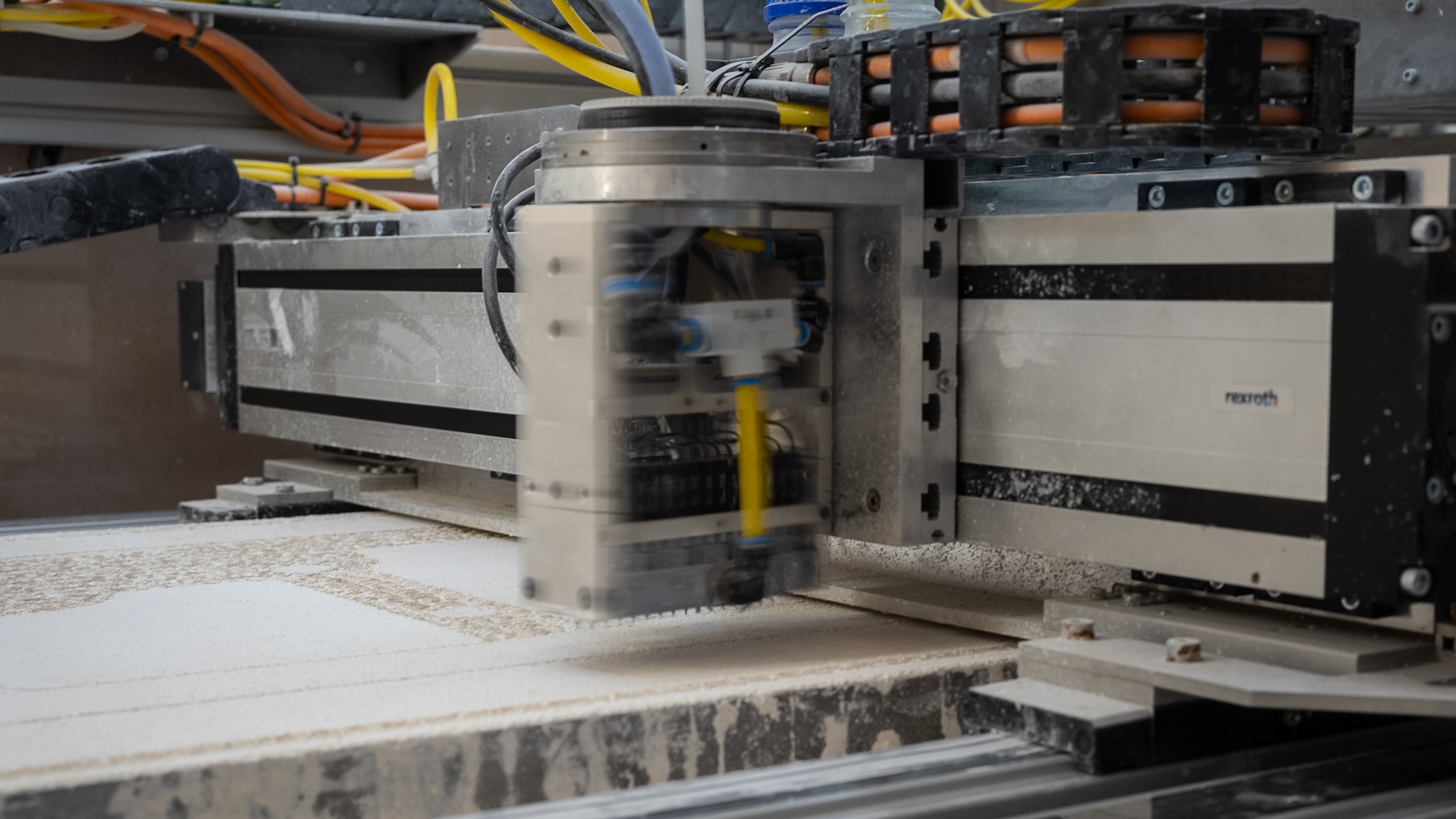

The installation proposes that architecture need not resist decay – it can evolve through it. It symbolically demonstrates this idea using a novel material: marble dust, a by-product from a quarry in South Tyrol. This dust, produced in volumes nearly equal to that of the extracted marble, is reconstituted using a binder jetting technique developed by Dr Pietro Odaglia at the Institute of Technology in Architecture, ETH Zürich.

Pietro Odaglia is a postdoctoral senior researcher at the Digital Building Technologies (DBT) group at ETH Zürich, where his work on binder jet 3D printing for architecture has evolved since his doctoral studies. The printing system used to produce Anti-Ruin is an updated version of the system deployed in an earlier project ARZO, which explored the challenges of on-site fabrication by relocating the printing setup to a remote quarry and working with locally sourced materials. That printed prototype, a funicular floor element designed by the Block Research Group (BRG) at ETH Zürich, was exhibited at the 2023 Venice Biennale. Developed in collaboration with the University of Applied Sciences and Arts of Southern Switzerland (SUPSI) and supported by the externe Seite National Centre of Competence in Research Digital Fabrication (NCCR DFAB), ARZO introduced Geopolymer Binder Jetting (GeoBJT): a reconfigured hardware–software platform tailored for structural-scale components made from local industrial waste, such as marble dust, and an expanding range of mineral binders.

“Anti-Ruin offered me the chance to test the new functionalities implemented after ARZO, with the added complexity of relatively high-volume production, since we had only a few weeks to finalise all 14 parts – roughly 2,000 litres of material in total,” says Pietro. “Printing and handling each element, averaging around 300 kilograms, offered valuable insights into the process. To my eye, each part of Anti-Ruin looks slightly better than the one before.”

The result is an artefact printed at millimetric resolution, prioritising durability and scalability, produced directly with recycled stone and industrial by-products, unlocking large-scale, structurally capable applications. Anti-Ruin offers a glimpse into an architectural future where material circularity meets digital precision. By combining recycled matter with computational design, the project challenges conventional notions of permanence, labour, and ornament in construction. It demonstrates how large-scale additive manufacturing can reintroduce richness, variation, and context-specificity into the built environment without relying on resource-intensive methods. As a prototype, it points towards a new synthesis of craft and automation, waste and form.

“If I had to choose the one aspect I’m most satisfied with, it would be the surface texture,” says Pietro. “It brings something new to 3D printing, somewhere between the coarse finish of concrete extrusion and the hyper-resolution of conventional binder jetting.”

Despite the focus on automation, the production of Anti-Ruin retained a hands-on dimension. “Working on a sculptural project, even within a tight schedule, requires attention to detail. I personally sanded and touched up each part until satisfied,” says Pietro. In today’s industrial context, where additive manufacturing is increasingly paired with automated post-processing, this approach reintroduces a space for digital–craft hybrids, suggesting new roles for authorship and refinement in computational fabrication.

Exhibiting at the Venice Biennale, a unique venue where architectural experimentation meets public and professional discourse, also opened up valuable conversations. “I had the opportunity to speak with leading figures in both design and fabrication,” says Pietro. “And I also want to mention how rewarding it was to collaborate with Levent and Danae, an exceptional team from the very first days of the project.”

Finally, when asked what comes next, Pietro has a clear and direct answer: “Spin-off. Completing Anti-Ruin convinced me once more that this technology offers a new bridge between design and material, and that it can open new dimensions in how we approach prefabrication. Now we just need to build the market for it!”

Project Credits:

Development of large-scale Binder Jet 3D Printer for construction elements: Dr. Pietro Odaglia (DBT, ETH Zurich)

Development of material system: Dr. Magda Posani, Dr. Vera Voney (Sustainable Construction, ETH Zurich)

Architectural Design: OZRUH

Structural Engineering: formDP

Photography: Lloyd Lee, Naomi Saka